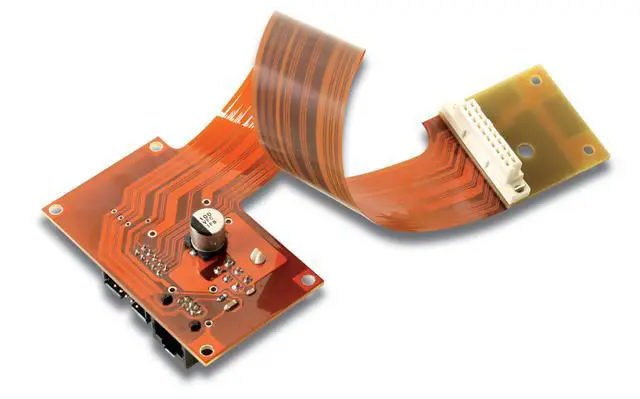

Flexible PCB Assembly

One-stop Flexible PCB Assembly Services

Your Trusted Partner for Flexible PCB Assembly Solutions

At Unit Circuits, we pride ourselves on our rich experience in providing top-notch flex pcb assembly services. From flexible PCB manufacturing and components procurement to FPCBA and testing, we offer comprehensive solutions to meet your needs. Our team of PCB industry experts works closely with you to ensure fast turnaround times and the highest quality results. Contact us today to discover how Unit Circuits can take your FPCBAs to the next level!

1. What is Flex PCB Assembly?

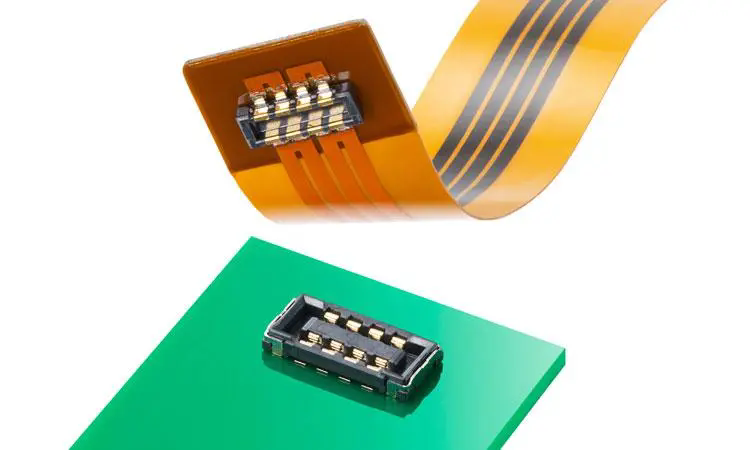

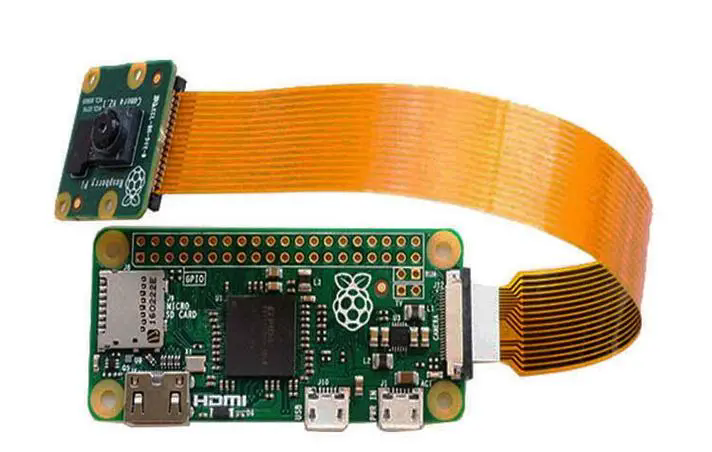

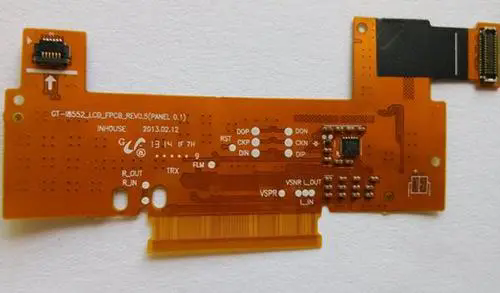

Flex PCB Assembly refers to the process of assembling electronic components onto flexible printed circuit boards (FPCBs).

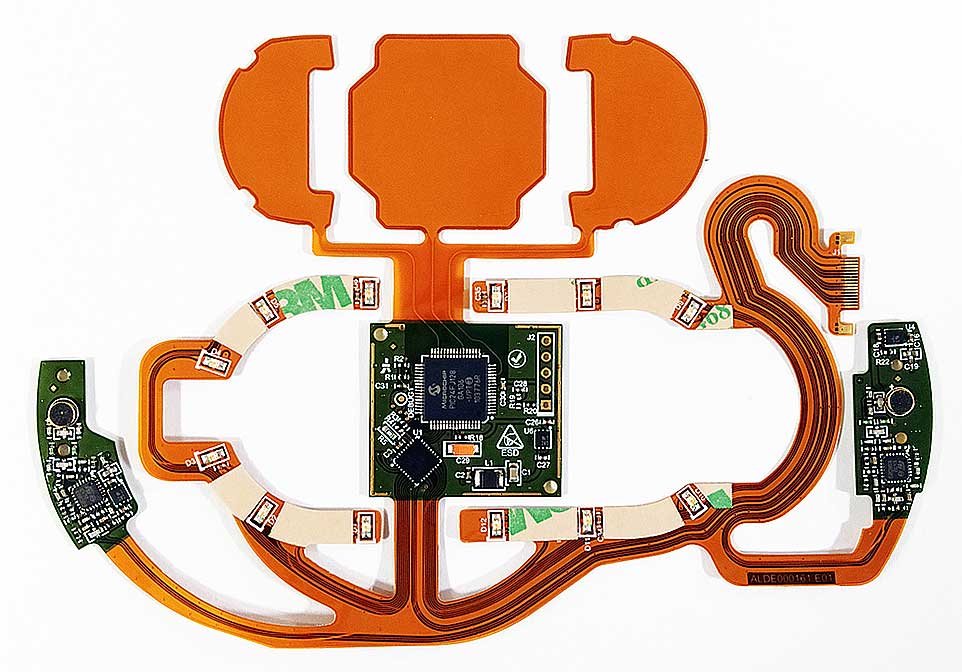

These boards are made from flexible plastic substrates like polyimide, allowing them to bend and conform to various shapes. Flex PCB Assembly is essential for creating compact, lightweight electronic devices that require dynamic bending or complex form factors. At Unit Circuits, we specialize in high-quality Flex PCB Assembly, ensuring that your electronic designs are both durable and flexible.

Difference Between Flex PCB Assembly and Traditional PCB Assembly

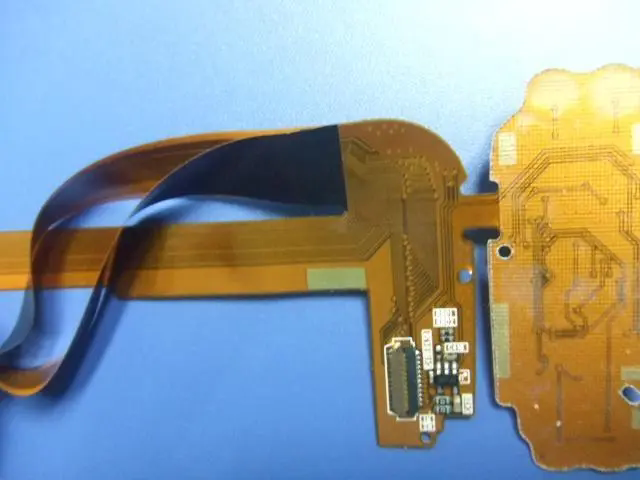

The primary difference between Flex PCB Assembly and traditional PCB Assembly lies in the substrate material and application. While traditional PCBs use rigid substrates like FR4, Flex PCBs use flexible materials like polyimide, allowing for dynamic bending and flexibility in tight spaces.

Flex PCB Assembly also often requires specialized handling and equipment to ensure components are properly placed without damaging the flexible substrate. As a result, Flex PCB Assembly is ideal for applications where space constraints, weight reduction, and product durability are essential.

Capability

| Item | Description |

| Assembly Technologies | SMT, TH, Mixed PCBA, BGA |

| PCB Types | Rigid, Flexible, Rigid-Flex PCBs, MC PCBs, Ceramic PCBs, Rogers PCBs |

| Parts Procurement | Full Turnkey, Partial Turnkey, Consigned/kitted |

| Component Size | Smallest 01005, Micro BGA, Fine Pitch Parts |

| Production Capacity | 8 SMT lines, 4 DIP Production Lines, Produce 2.5 million pcs per day |

| Soldering Types | Reflow Soldering, Wave Soldering |

| Repair & Rework | Ball Grid Array replacement, IR rework |

Why Many Standard EMS Providers Struggle with Flex PCB Assembly

Flex PCB Assembly is more complex than traditional PCB Assembly, which is why many standard EMS (Electronics Manufacturing Services) providers struggle with it. The challenges include:

- Specialized Equipment: Flex PCBs require precise handling and assembly equipment to avoid damaging the delicate flexible substrate.

- Component Placement: The flexible nature of the board requires careful component placement techniques to ensure reliability and performance.

- Thermal Management: Flex PCBs often face greater challenges in heat dissipation, requiring advanced thermal management solutions during assembly.

- Expertise and Experience: Flex PCB Assembly demands specialized knowledge and experience, which many standard EMS providers may lack. At Unit Circuits, our team is highly experienced in Flex PCB Assembly, offering solutions that meet the most demanding specifications.

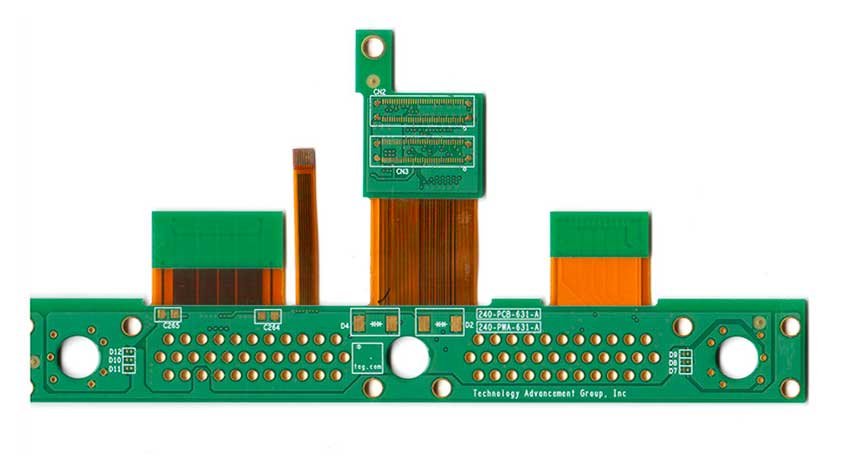

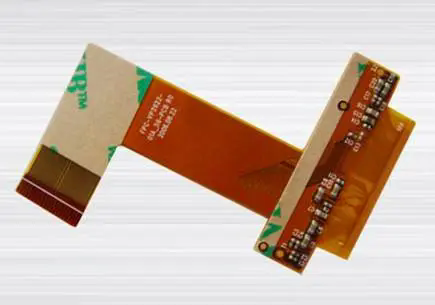

FPCBA Products

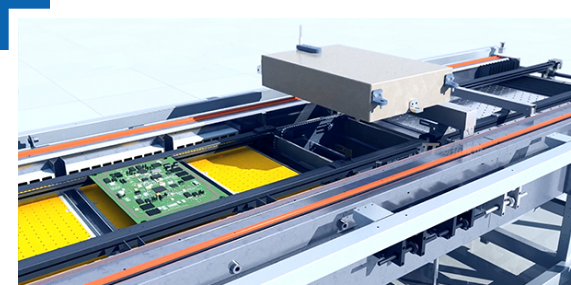

Assembly Process

Comprehensive, reliable, performance, validation, automated, functional testing for electronics.

Branded Partner :

Inspection Process

Pre-assembly, packaging, value, verification, station parts inspection process.

Initial, detailed, verification, quality, First Article Inspection ensures compliance.

Comprehensive, reliable, performance, validation, automated, functional testing for electronics.

Quality Control

Accurate Testing

Real-Time Tracking

FAQs about FPCB Assembly

Our flex PCB assembly services include component sourcing, surface-mount and through-hole component assembly, soldering, testing, and final assembly, providing a complete solution from prototype to production.

Yes, we can source all necessary components including hard-to-find and specialized components. We ensure all parts are genuine and meet our quality standards.

We perform functional testing, in-circuit testing, and automated optical inspection (AOI) to ensure every assembled flex PCB functions as intended and meets all performance criteria.

We offer flexible change management processes to accommodate revisions or changes during the assembly process, ensuring that final products align with your updated requirements.

Yes, we offer rapid prototyping services that allow you to test and refine your designs before moving to full production, reducing risks and potential costs.

We can handle everything from small batch productions for prototypes to large-scale manufacturing runs, adapting our production lines to your volume requirements.

We follow strict IPC standards for PCB assembly and conduct multiple quality checks and testing throughout the assembly process to ensure reliability.

Yes, our assembly processes comply with environmental regulations, including RoHS and REACH, ensuring that products are not only high-quality but also environmentally friendly.