Flexible PCB Manufacturing

Customized Flex PCB Fabrication

Your Trusted Partner for flex PCB fabrication

For businesses seeking cutting-edge flexible PCB solutions, Unit Circuits stands out with its exceptional experience and comprehensive capabilities. Our expertise in flexible and rigid-flex PCB manufacturing ensures that we meet the most demanding specifications and quality standards. Whether you need custom designs or rapid prototyping, our team is equipped to deliver innovative and reliable flex PCB products tailored to your specific needs.

What is a Flexible PCB?

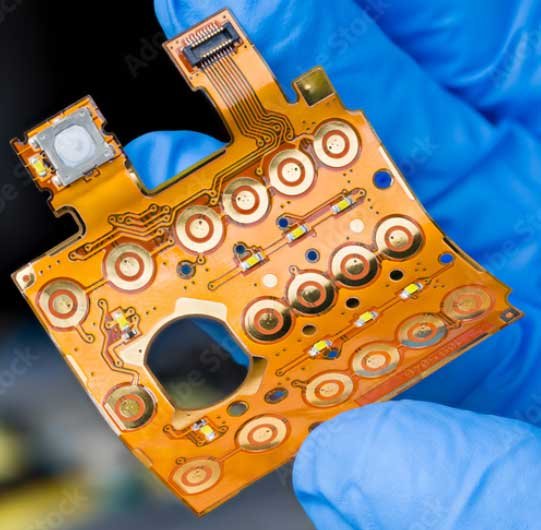

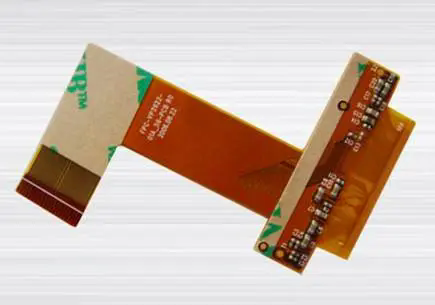

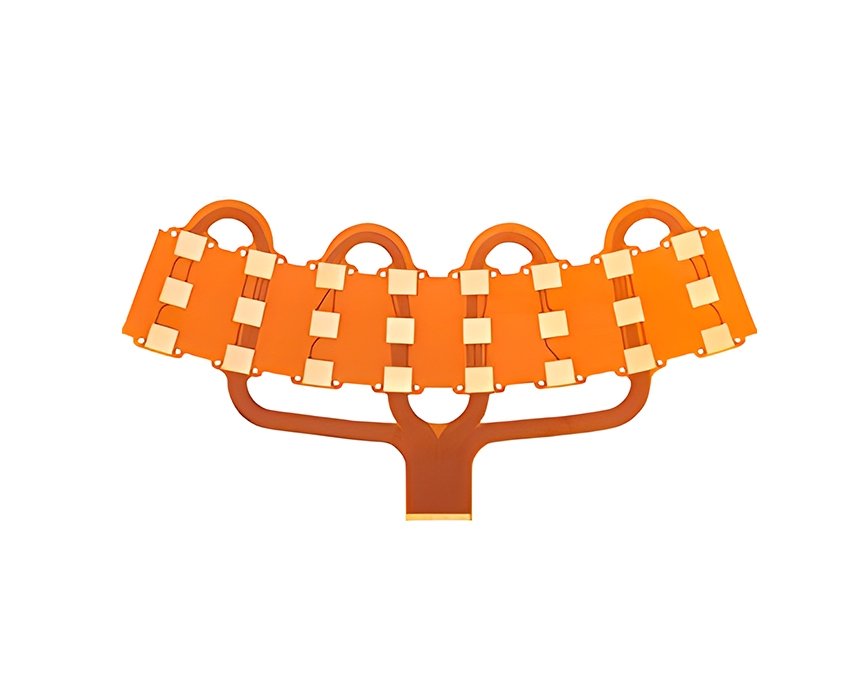

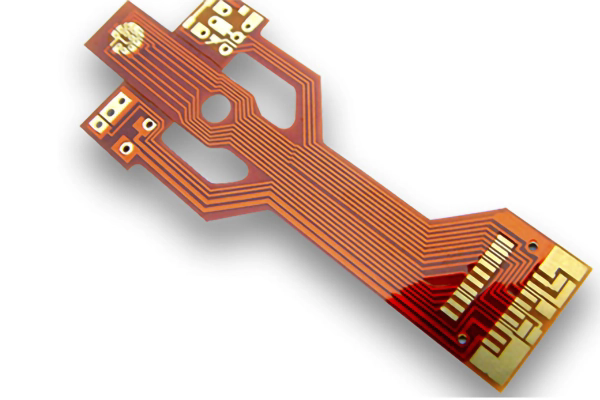

Flexible PCBs, also known as flex circuits or flexible printed circuit boards, are an integral part of modern electronics. These circuits consist of a thin, flexible insulating polymer film with conductive circuit patterns, often coated with a protective polymer layer to safeguard the circuits. Since their introduction in the 1950s, flexible PCBs have become a crucial technology for interconnecting electronic components, especially in advanced electronic products. At Unit Circuits, we specialize in providing customized flexible PCB solutions, ensuring high-quality, reliable performance for complex electronic applications.

High-Temperature and High-Density Applications

Flexible PCBs are often manufactured using polyimide or similar polymers, which offer superior heat dissipation compared to traditional rigid circuit board materials. This makes them ideal for placement in challenging environments where heat could compromise the performance of rigid boards.

Our flexible PCBs at Unit Circuits are engineered to withstand extreme temperatures ranging from -200°C to 400°C, making them particularly suited for demanding applications like borehole measurements in the oil and gas industry. These characteristics, combined with the need for compact and reliable solutions in industrial environments, make flexible PCBs the preferred choice for advanced industrial sensor technologies.

Moreover, the high-temperature resistance of our flexible circuits is complemented by excellent chemical resistance, radiation resistance, and UV exposure durability. When paired with the capability to manage impedances in high-density designs, our flexible PCB solutions offer significant advantages for manufacturers seeking robust, high-performance electronic components.

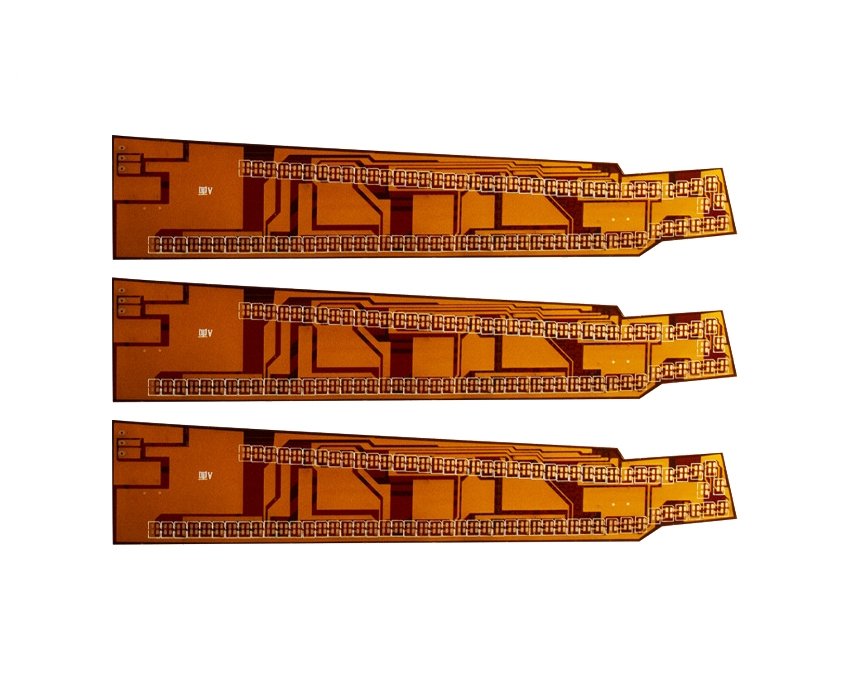

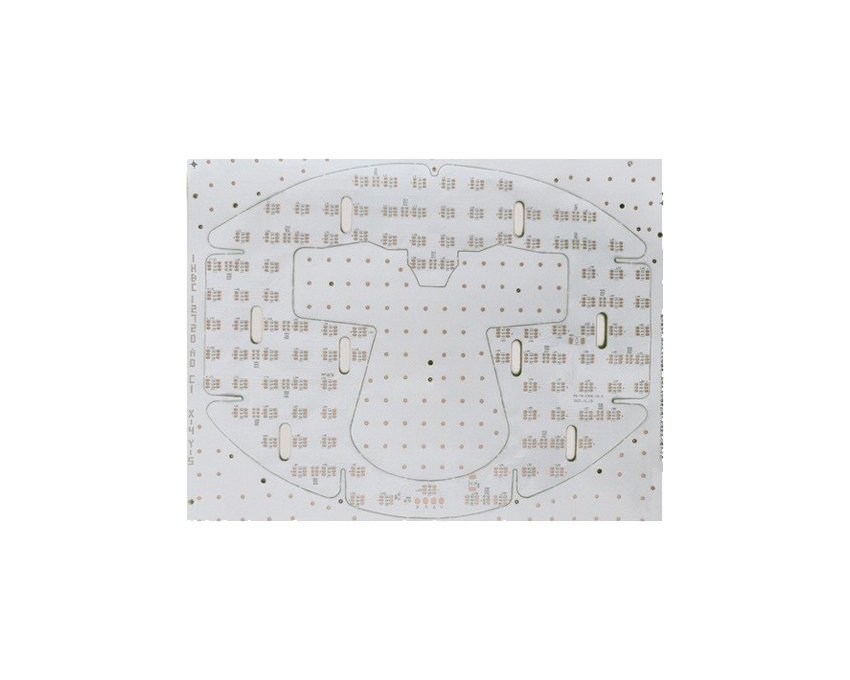

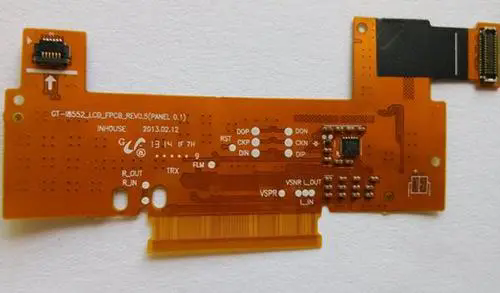

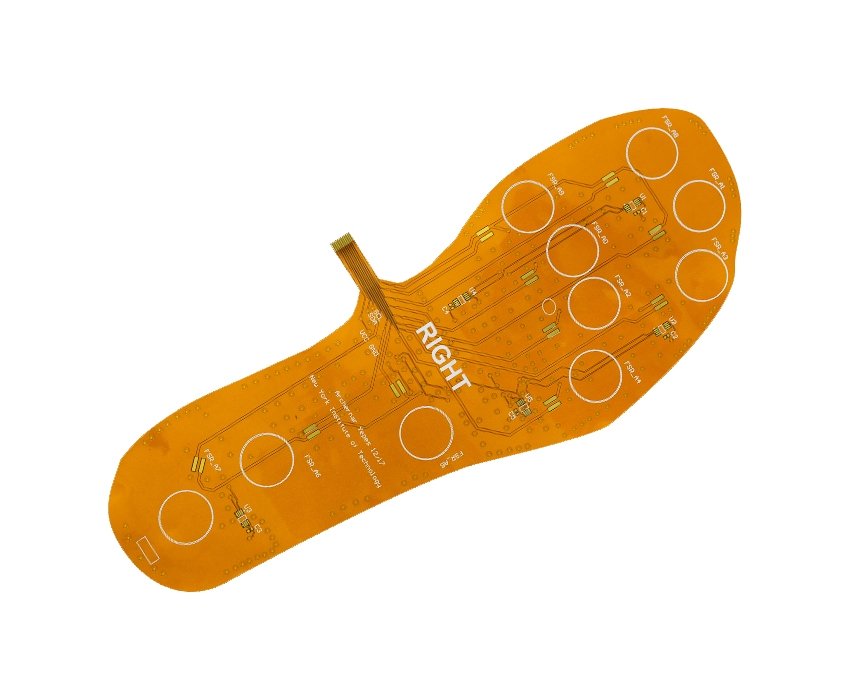

Flexible PCB Samples

Why Not Make All Circuit Boards Flexible?

While flexible circuit boards offer significant advantages, they aren’t suited for every application, particularly when cost efficiency is a priority. Rigid circuit boards are typically more cost-effective to manufacture and assemble, especially in high-volume production environments.

For most innovative products, the optimal solution often involves a combination of flexible and rigid PCBs. This approach leverages the flexibility where it’s essential while using rigid boards to maintain lower manufacturing and assembly costs.

At Unit Circuits, we also specialize in hybrid rigid-flex PCBs, which are commonly used in applications like laptop computers and medical devices. These designs connect rigid boards with flexible circuits, providing a robust solution that meets various engineering demands by harnessing the strengths of both technologies.

If you’re unsure whether your product would benefit more from flexible, rigid, or hybrid PCB designs, our expert team is here to help. Contact us for a consultation to determine the best PCB solution for your specific needs.

Check Unit Circuits’ Flex PCB manufacturing capabilities in the following table:

Flex PCB Manufacturing Capability

|

Item |

Prototype |

Production |

|

Types |

Single-sided, Double-sided, Layered, Hollow, Multi-layer |

Single-sided, Double-sided, Layered, Hollow, Multi-layer |

|

Layer Count |

1-16 layers for flexible circuits |

1-12 layers for flexible circuits |

|

Board Dimensions |

250*4000mm |

250*4000mm |

|

Board Thickness |

0.06-0.4mm |

0.06-0.4mm |

|

Minimum Trace Width/Spacing |

0.045mm/0.045mm |

0.045/0.045MM |

|

Materials |

PI (Polyimide), PET (Polyester), Electrolytic Copper, Rolled Copper |

PI (Polyimide), PET (Polyester), Electrolytic Copper, Rolled Copper |

|

Finished Board Thickness Tolerance |

±0.03mm |

±0.03mm |

|

Copper Thickness |

12UM 18UM 36UM 70UM |

12UM 18UM 36UM 70UM |

|

Insulation Layer Thickness |

12.5um 25UM 50UM |

12.5UM 25UM 50UM |

|

Minimum Drill Hole Size |

CNC Drilling: 0.15 mm Laser Drilling: 0.1 mm |

CNC Drilling: 0.15 mm Laser Drilling: 0.1 mm |

|

Hole Diameter Tolerance (PTH) |

±0.05mm |

±0.05mm |

|

Stiffener |

FR4/PI/PET/SUS/PSA |

FR4/PI/PET/SUS/PSA |

|

Surface Finishes |

Immersion Gold, Immersion Silver, Gold Plating, Tin Plating, OSP |

Immersion Gold, Immersion Silver, Gold Plating, Tin Plating, OSP |

|

Impedance Control |

50Ω -120Ω |

50Ω -120Ω |

|

Standards & Certifications |

Factory standard; GB; IPC-650; IPC-6012; IPC-6013 Class II; IPC-6013 Class III; Military standard; others. |

Factory standard; GB; IPC-650; IPC-6012; IPC-6013 Class II; IPC-6013 Class III; Military standard; others. |

|

Environmental Certifications |

RoHS, SGS Testing, REACH 168 item report. |

RoHS, SGS Testing, REACH 168 item report. |

Blind/Buried Vias or Microvias

Via in Pad

Countersink/Counterbore Hole

Half-cut/Castellated Hole

Gold Fingers

Edge Plating

Kapton Tape

RoHS Compatibility

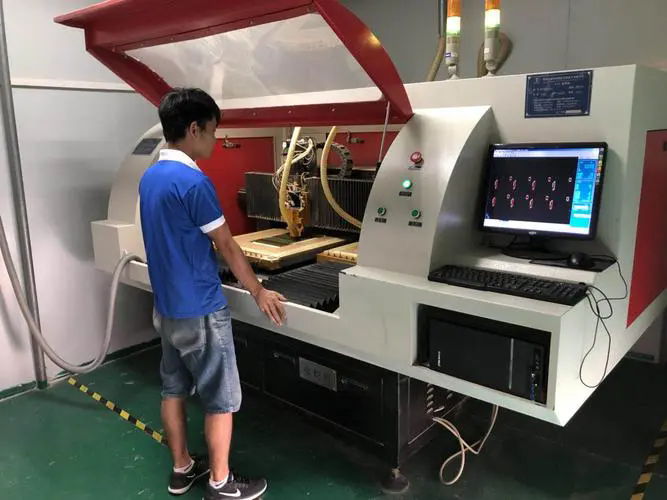

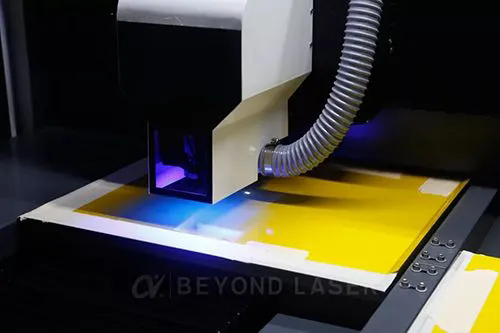

Fabrication Process for Flexible PCB

Branded Partner :

Inspection Process for Flexible PCBA

Pre-assembly, packaging, value, verification, station parts inspection process.

Initial, detailed, verification, quality, First Article Inspection ensures compliance.

Comprehensive, reliable, performance, validation, automated, functional testing for electronics.

Quality Control

Accurate Testing

Real-Time Tracking

FAQs about flexible PCB Manufacturing

Flexible PCBs are ideal for applications requiring high flexibility, limited space, or lightweight solutions. Common applications include wearable technology, mobile devices, and medical equipment where adaptability and durability are crucial.

We employ advanced manufacturing processes and rigorous testing protocols, including electrical and thermal testing, to ensure each flexible PCB meets high reliability standards suitable for demanding environments.

Absolutely! We can customize flexible PCBs to fit your specific requirements for shape, flexibility, and functionality, ensuring perfect integration into your product design.

Our flexible PCBs are made using high-quality materials such as polyimide or polyester (PI or PET), which provide excellent flexibility and heat resistance, ensuring performance under various environmental conditions.

Lead times vary based on design complexity and quantity. Typically, prototype orders are completed within 1-2 weeks, while larger production orders may require more time to ensure quality and precision.

We offer expedited services for urgent orders. Please contact us with your requirements, and we will work to accommodate your schedule without compromising on quality.

We accept a range of file formats including Gerber, CAD, and Eagle files. We can also assist in converting other file types to ensure compatibility.

Yes, all our PCBs comply with IPC standards, and we can provide additional certifications such as RoHS, UL, and ISO upon request.