Industrial Control

Widely used in: Robotic Arms, Programmable Logic Controllers (PLCs), Industrial Sensors, Motor Controllers

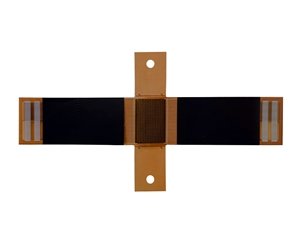

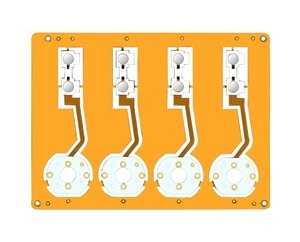

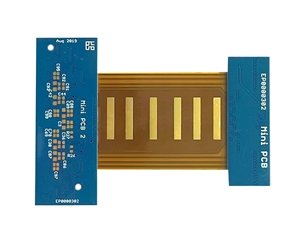

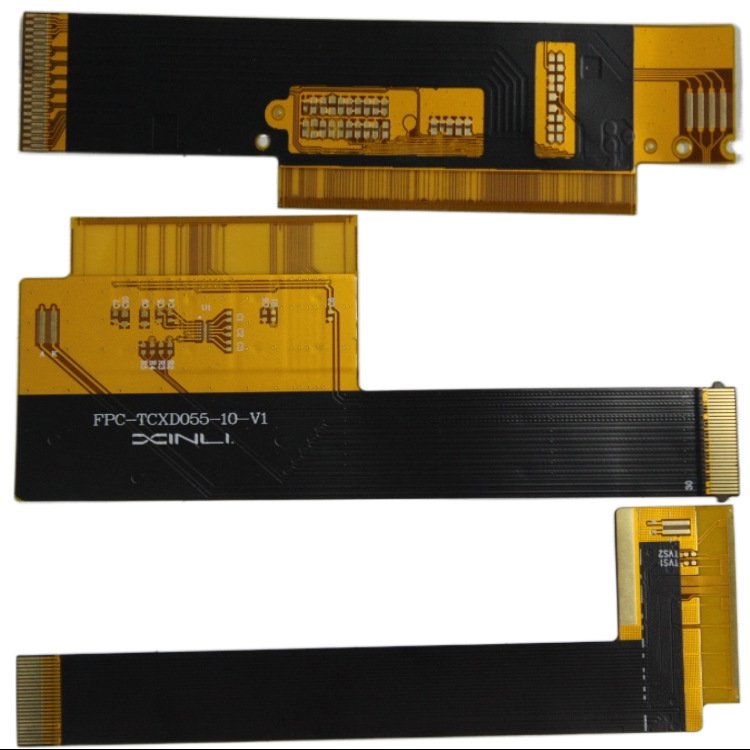

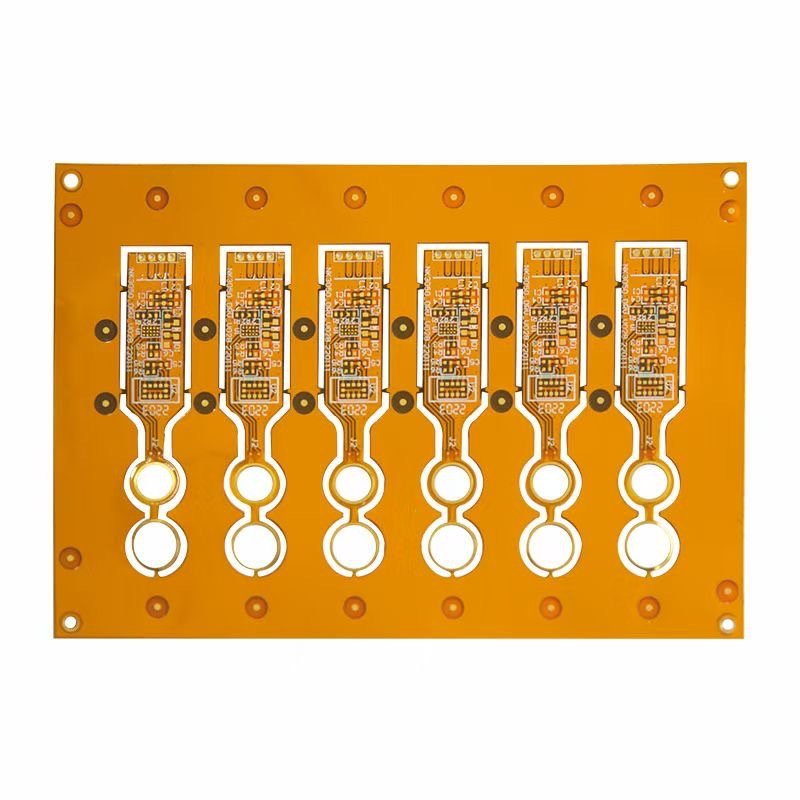

Industrial Control Flexible PCB

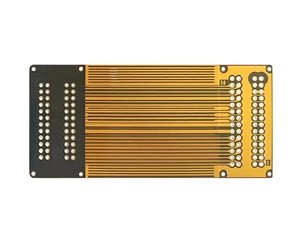

In the realm of industrial control, efficiency, reliability, and innovation are key. Flexible PCBs (Printed Circuit Boards) are at the forefront of these advancements, providing robust solutions for complex industrial applications.

At Unit Circuits, we understand the unique challenges you face in the industrial control sector. Our expertise in manufacturing high-quality flexible PCBs ensures you receive products that meet your exact specifications and exceed expectations. With fast quoting, no minimum order quantities, and rapid delivery, we support your product development and manufacturing processes efficiently.

Get your Industrial Control Solution

USB cameras are widely used in access control systems, facial recognition, turnstiles, smart robots, and automated kiosks.

Widely used in robotics, tunnel deformation measurement, coal mine height measurement, measuring the distance between train carriages, automotive parts assembly, and engineering surveying.

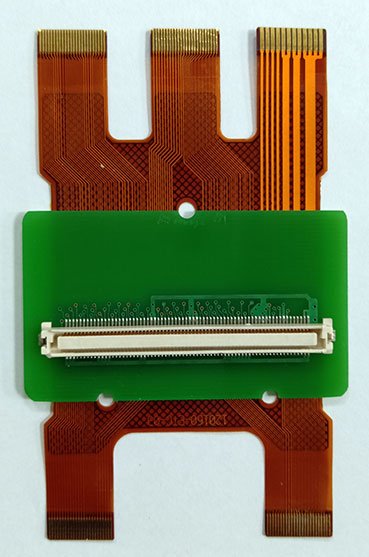

LCD displays are used in various fields, including consumer electronics, medical devices, automotive dashboards, industrial equipment, and aviation instruments.

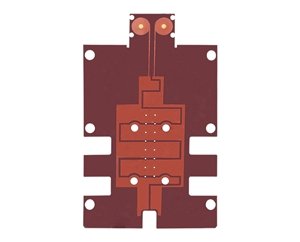

Industrial control switches are used in manufacturing automation, process control, machinery, robotics, power distribution, and HVAC systems.

Aerial display screens are used in fields such as drone surveillance, aerial photography, real-time mapping, environmental monitoring, and agricultural surveying.

Used in motor controllers, flexible PCBs help in achieving precise control over motors in various industrial applications, from conveyor systems to machinery drives.

Our Specialized Services

Tailored for Your Needs

Specialized and specific, our services are customized to meet your precise requirements, ensuring professional and reliable results every time.

Flexible PCBs enable smaller, more compact device designs, crucial for space-limited medical applications.

Flexible PCBs can endure bending and flexing, essential for wearable and portable medical devices.

High-quality materials and precise manufacturing ensure your devices perform reliably under demanding conditions.

Flexible PCBs can be shaped to fit unique designs, allowing for innovative and standout medical devices.

The thin, flexible nature of these PCBs reduces the overall weight of medical devices, enhancing patient comfort and ease of use.

The flexibility of these PCBs allows for more efficient signal transmission and reduced interference, improving overall device performance.

Capability

Item | Production |

Types | Single-sided, Double-sided, Layered, Hollow, Multi-layer |

Layer Count | 1-12 layers for flexible circuits 2-16 layers for rigid-flex circuits |

Board Dimensions | 250*4000mm |

Board Thickness | 0.06-0.4mm for flexible circuits 0.25-6.0mmfor rigid-flex circuits |

Minimum Trace Width/Spacing | 0.045/0.045MM |

Copper Thickness | 12UM 18UM 36UM 70UM |

Insulation Layer Thickness | 12.5UM 25UM 50UM |

Minimum Drill Hole Size | CNC Drilling: 0.15 mm Laser Drilling: 0.1 mm |

Branded Partner :