Medical Devices

Widely used in: Wearable medical devices, diagnostic instruments for healthcare monitoring and analysis.

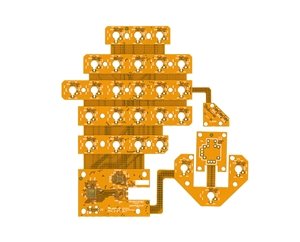

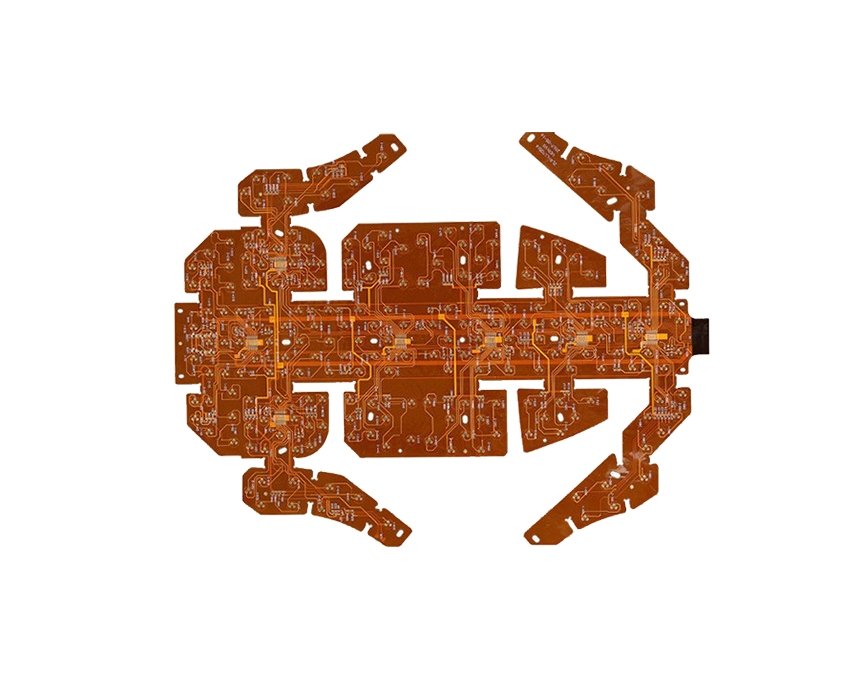

Medical Devices Flexible PCB

In the dynamic field of medical devices, the need for reliable, high-performance components is paramount. That’s where flexible PCBs come into play, offering a myriad of benefits that are essential for advanced medical technology.

At Unit Circuits, we understand the challenges you face in the medical device industry. Our expertise in manufacturing high-quality flexible PCBs ensures that you receive products that meet your exact specifications and exceed your expectations. With our commitment to fast quoting, no minimum order quantities, and rapid delivery, you can trust us to support your product development and manufacturing processes efficiently.

Get your Medical Devices solution

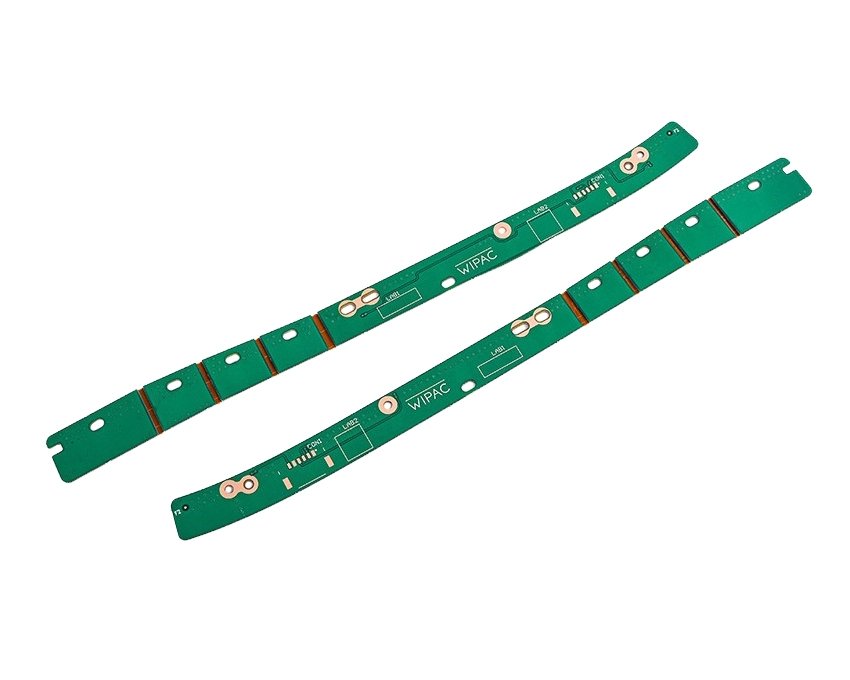

Laser Hair Cap

Flexible PCBs enable compact, efficient design in laser hair caps for optimal scalp treatment.

Neck Therapy Devices

Flexible PCBs ensure precision and adaptability in neck therapy devices for effective treatment

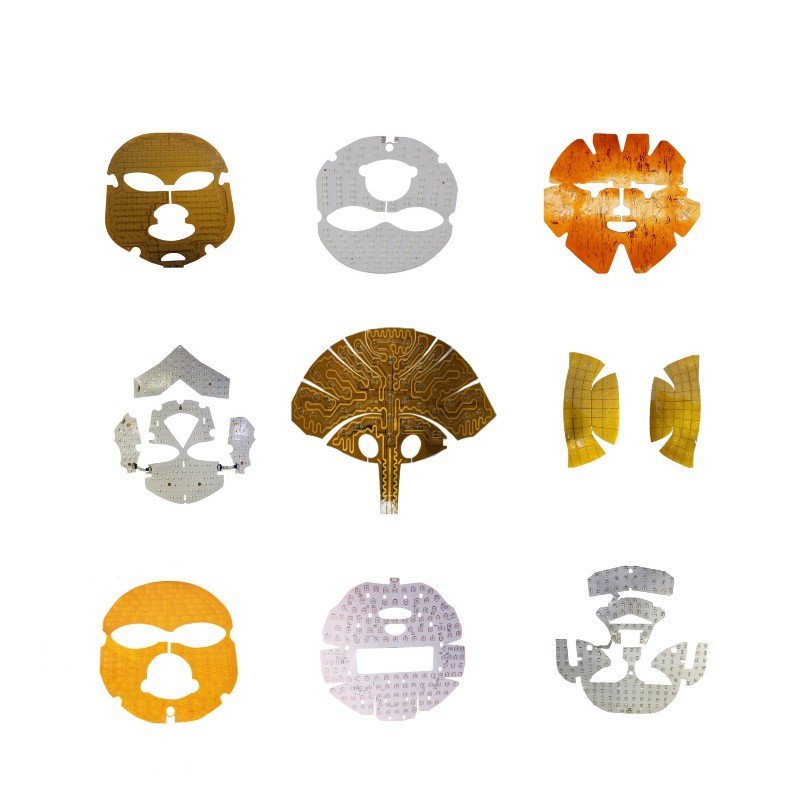

LED Mask FPC

Flexible PCBs enable sleek, conforming designs in LED masks for effective facial treatments.

Feet Sensor FPC

Flexible PCBs provide accurate, responsive measurements in feet sensors for enhanced mobility analysis.

Lumbar Therapy Devices

Flexible PCBs offer precision and comfort in lumbar therapy devices for effective back treatments.

Ventilators

Flexible PCBs ensure reliable, compact circuitry in ventilators for efficient respiratory support.

Our Specialized Services

Tailored for Your Needs

Specialized and specific, our services are customized to meet your precise requirements, ensuring professional and reliable results every time.

Flexible PCBs enable smaller, more compact device designs, crucial for space-limited medical applications.

Flexible PCBs can endure bending and flexing, essential for wearable and portable medical devices.

High-quality materials and precise manufacturing ensure your devices perform reliably under demanding conditions.

Flexible PCBs can be shaped to fit unique designs, allowing for innovative and standout medical devices.

The thin, flexible nature of these PCBs reduces the overall weight of medical devices, enhancing patient comfort and ease of use.

The flexibility of these PCBs allows for more efficient signal transmission and reduced interference, improving overall device performance.

Capability

Item | Production |

Types | Single-sided, Double-sided, Layered, Hollow, Multi-layer |

Layer Count | 1-12 layers for flexible circuits 2-16 layers for rigid-flex circuits |

Board Dimensions | 250*4000mm |

Board Thickness | 0.06-0.4mm for flexible circuits 0.25-6.0mmfor rigid-flex circuits |

Minimum Trace Width/Spacing | 0.045/0.045MM |

Copper Thickness | 12UM 18UM 36UM 70UM |

Insulation Layer Thickness | 12.5UM 25UM 50UM |

Minimum Drill Hole Size | CNC Drilling: 0.15 mm Laser Drilling: 0.1 mm |

Branded Partner :