Table of Contents

The Difference between FFC and FPC

Do you have questions to clarify these two: FFC and FPC? When I see pictures of both, why they are so similar? How can we tell the difference? Today let us discuss this from two aspects: definition and application. Hope this simple article can help you learn something about FFC and FPC.

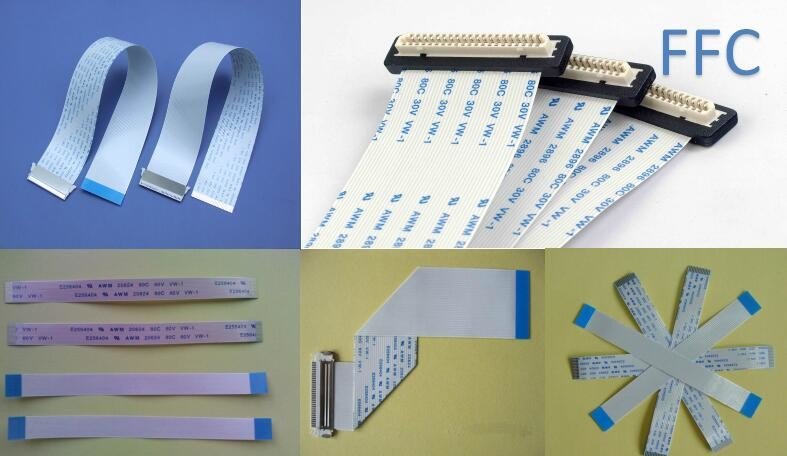

1.FFC

FFC (Flexible flat cable) refers to any variety of electrical cable that is both flat and flexible. FFC is a miniaturized form of ribbon cable, consists of flat and flexible plastic film base, with multiple metallic conductors bonded to one surface.

Flexible flat cables are used in place of round cables for easy cable management, especially in high-flex applications. They usually take up less space than round cables, often offering better EMI/RFI suppression and eliminating wire coupling issues.

Pitch:0.5mm, 0.625mm, 0.635mm, 0.8mm, 1.0mm, 1.25mm, 1.27mm, 2.0mm, 2.54mm

Application:

printer connection between the head and the motherboard, plotters, scanners, copiers, stereos, LCD appliances, fax machines, DVD players and other products, a variety of signal transmission and plate board connections. In modern electrical equipment, FFC Cables can be found almost everywhere.

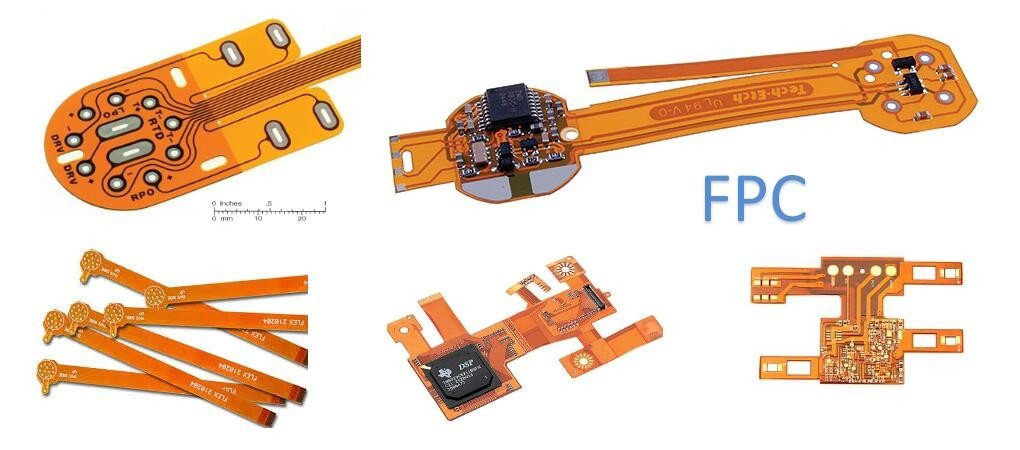

2.FPC

FPC(Flexible printed circuit) refers to a thin insulating polymer film having conductive circuit patterns affixed there to and typically supplied with a thin polymer coating to protect the conductor circuits.

There are many different kinds of FPC, including single layer, double sided, multilayer flex circuit.

Application:

Flexible circuits are used in cell phones, LCD televisions, antennas, and laptops. Flexible circuits have evolved and help provide durability and reliability. Flexible circuits are also used in the aviation field. Other applications of flexible circuits are in hearing aids, calculators, cameras, printers, and in satellites.

Regarding manufacturing methods, FPC make circuits by etching on FCCL then laminated into different layers, while FFC is just simple lamination of PET and flat copper wires, the thickness of FFC is much bigger than FPC.

Note: we’re specialized in FPC manufacturing not FFC.