Table of Contents

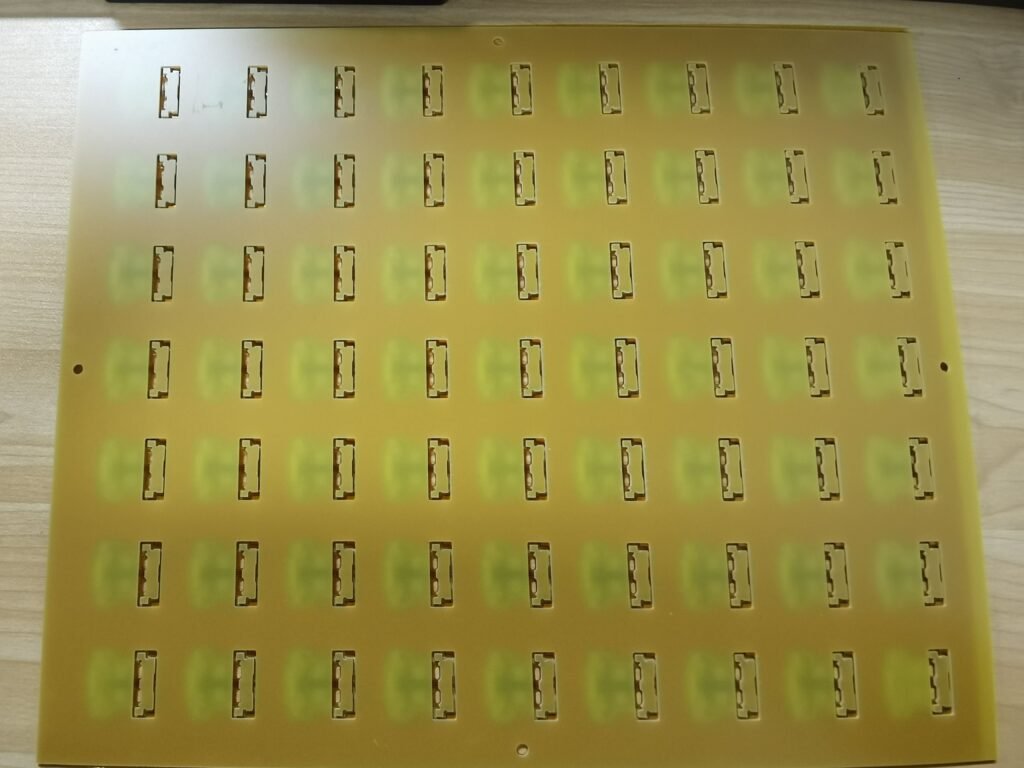

Why It Is Necessary to Apply FR4 Stiffener to Panel Waste Area?

In the world of flexible PCBs, durability and flexibility are key. But keeping these flex boards safe during manufacturing, shipping, and assembly is tough. One of the best ways to do that is to stick a FR4 stiffener in the panel waste area. But why is it necessary? Let’s talk about what these stiffeners do and why they are so important for keeping them working for a long time.

What is FR4 Stiffener?

Why Apply FR4 Stiffeners to Panel Waste Areas?

During the production and assembly of flexible PCBs, there is always a risk that they could be bent, warped, or broken. Applying an FR4 stiffener to the panel waste area is a good way to fix this problem. Here’s why:

- Protects During Shipping and Handling: Flex boards are bendy, so they can get hurt when they are shipped. If you stick a stiffener in the waste area, it makes the panel stiff so it doesn’t bend, twist, or get hurt when it’s shipped.

- Prevents Warping During Assembly: The assembly process can place stress on flexible PCBs. By reinforcing the waste areas with stiffeners, PCB Assembly Provideer can maintain the integrity of the boards during assembly, minimizing the risk of warping or misalignment.

- Cost Efficiency: Stiffeners cost a little bit of money to make but they ultimately help reduce returns and quality control issues caused by damaged goods. If you’re in a fancy industry like aerospace or automotive, it’s worth it to spend a little bit of money to make sure your stuff is good.

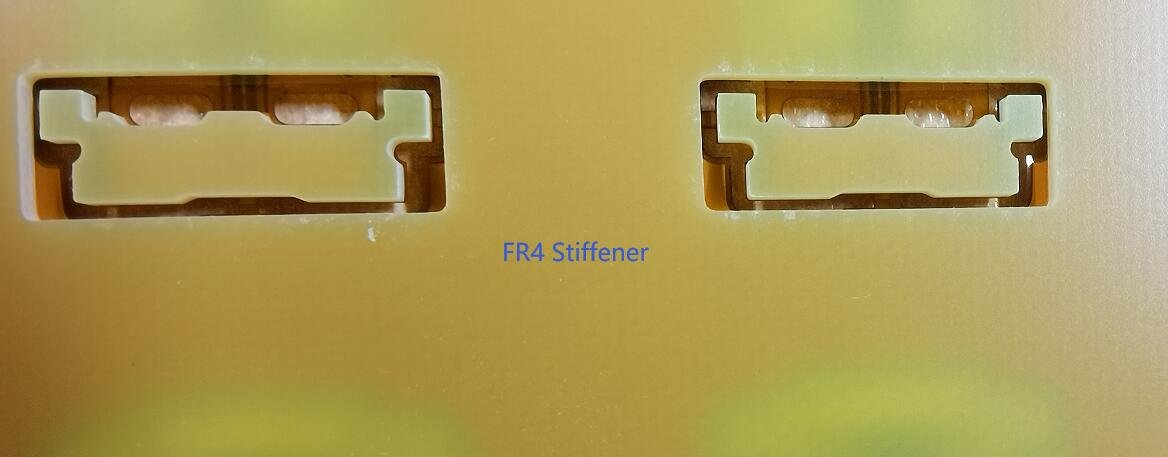

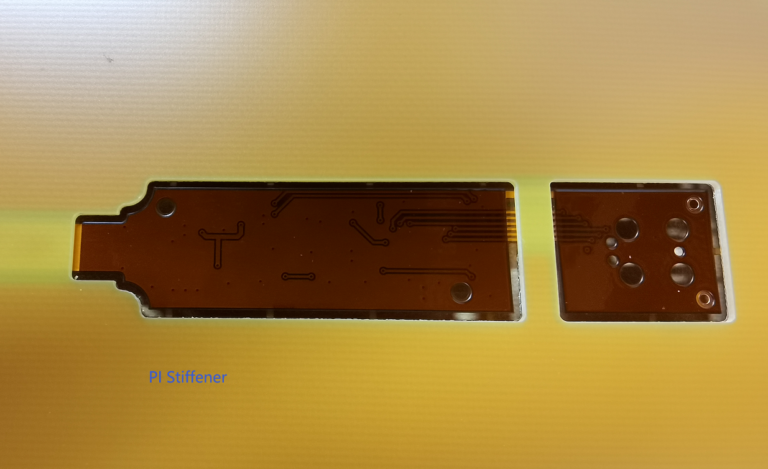

What Is the Difference Between FR4 and Polyimide Stiffeners?

- FR4: FR4 is a rigid laminate material made from woven glass fibers and epoxy resin. It is the most common material used for stiffeners due to its strength and cost-effectiveness. However, it lacks flexibility and can degrade in high-vibration environments.

- Polyimide: In contrast, polyimide stiffeners are more flexible and better suited for applications that experience extreme heat and vibration. Polyimide is more expensive but offers better thermal stability and vibration resistance, making it ideal for industries like aerospace and automotive.

When Should You Use FR4 Stiffeners?

Stiffener Type, Material, and Function of FR4 Stiffeners

- Laminate Bonding: You can stick FR4 stiffeners right on your flex board with heat or glue. This way, they stay on there forever and don’t come off.

- Panel Waste Application: For added rigidity, stiffeners are often applied to the panel waste areas, especially in cases where the boards are being delivered in panel form. This not only reinforces the flexible board during shipping but also simplifies handling and assembly, reducing potential damage from manual handling.

Benefits of FR4 Stiffeners in Flexible PCB Manufacturing

- Improved Handling: By applying FR4 stiffeners to the panel waste area, manufacturers improve the handling process, making it easier to insert components and connectors without risking damage to the board.

- Long-Term Durability: FR4 stiffeners make flex boards stronger by keeping them from getting bent or broken, which can make your circuits stop working or which can lead to circuit failure or product returns.

- Cost Savings: If you make sure your flex boards get where they are going without getting hurt, companies save on replacement costs, repairs, and potential project delays caused by damaged products.

FAQs About FR4 Stiffeners

Conclusion:

In conclusion, the application of FR4 stiffeners in the panel waste areas of flexible circuit boards is a critical step in ensuring the durability, stability, and successful delivery of your product. For industries requiring high precision and reliability, such as automotive, aerospace, or medical devices, FR4 stiffeners help prevent bending and damage during transportation and assembly. By reinforcing these areas, you can guarantee a higher-quality product and fewer post-delivery issues, ultimately saving time and money.